Services

We offer a wide range of services, from various metal cutting methods to the design and production of a complete solution from a concept. Our main strength lies in offering complete solutions, product development and prototyping capabilities.

Metalworks

We specialise in project-based production in small batches. Thanks to our on-site capabilities and equipment, excellent cooperation partners, and network of suppliers, we are able to offer a wide range of complete metalworking solutions.

Laser cutting

Laser cutting is the fastest method of cutting sheet metals and has a low thermal impact on the material. The details do not require post-processing and the cut surface remains smooth. In addition, it is possible to cut holes in the parts in the required dimensions, and the finished product has a very high degree of accuracy.

Gas cutting

In addition to laser cutting, we also offer gas cutting, which is highly suited method for cutting carbon steel parts, if extremely precise tolerances are not required.

Roll-forming

Roll-forming is the processing of sheet metal via pressing to manufacture cylindrical and conical products.

Bending

Bending is a cold treatment method of sheet metal from various steels to produce products of complex shapes. The maximum thickness of the workpiece is determined by the sheet material.

CNC milling and turning

CNC mills and lathes can process metals mechanically and in extremely precise dimensions, and make parts with complex geometries that cannot be produced from sheet metal, for example.

Mechanical engineering and final assembly

We carry out assembly works on machinery and other complex products. We install the necessary special components and solutions, such as electrical and weak-current systems, automation, hydraulics and pneumatics, as well as water and sewerage systems with treatment and purification and heating and ventilation mechanisms.

Manufacturing defence industrial solutions

During our nearly 20 years of operation, we have significantly developed metalworking and mechanical engineering capabilities of the company, and in the last 10 years, applied it to the production of solutions in areas with industry-specific requirements, such as the medical and defence industries.

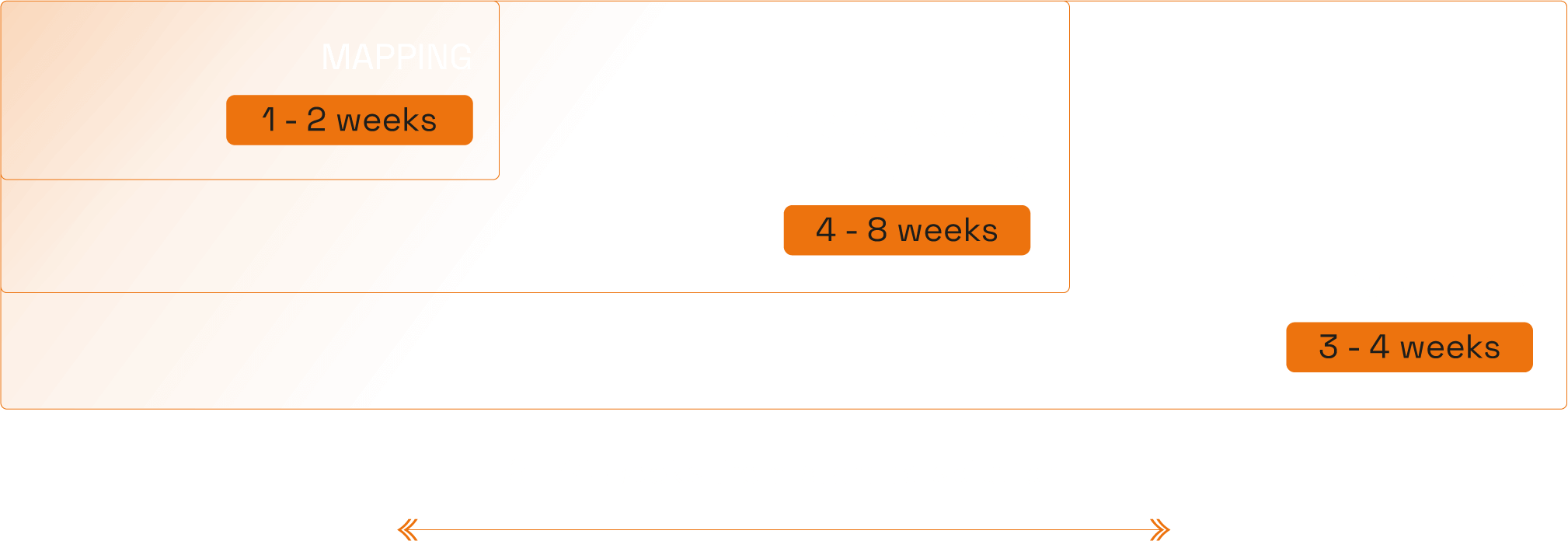

Designing and prototyping (Protoduction)

Protoduction allows us to map the customer’s needs, design the solution, and then prototype it within a short period of time or also to produce it in batches.